The project takes place from September 5th, 2016 to January 13th, 2017

The Factory Futures Project is the logical next episode of Global Factory 1&2 and Digital Farm Project 1&2 (see “previous project”). After exploring mechanical and industrial fields in 2012-2013 and the link between mechanic and agronomics in 2014, we are launching the 5th edition of the GLOBAL ENGINEERING EXPERIENCES using only the 3DEXPERIENCE Platform, which gathers DS software like CATIA, 3DSwym, ENOVIA, DELMIA among many others!

“Worldwide students imagine the Industry of the future”

Factory Futures brings students dispersed across the planet through a problem based learning experience that combines various disciplines, mechanical, systems, industrial, aeronautical engineering to project management and communication sciences. We hope that it will arouse students’ interest because we will approach different fields of study such as Engineering, Communication, Management, Education, Innovation and Architecture.

Connected through cutting-edge digital practices and tools like Dassault Systèmes 3DEXPERIENCE Platform, students will build a true competence in working across distance, cultures and disciplines.

Factory Futures at a glance

- Serves as capstone project, Master or international internship

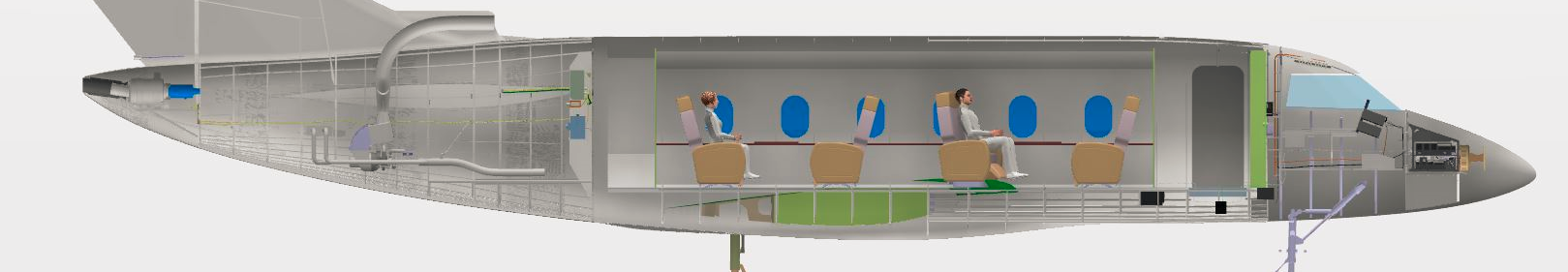

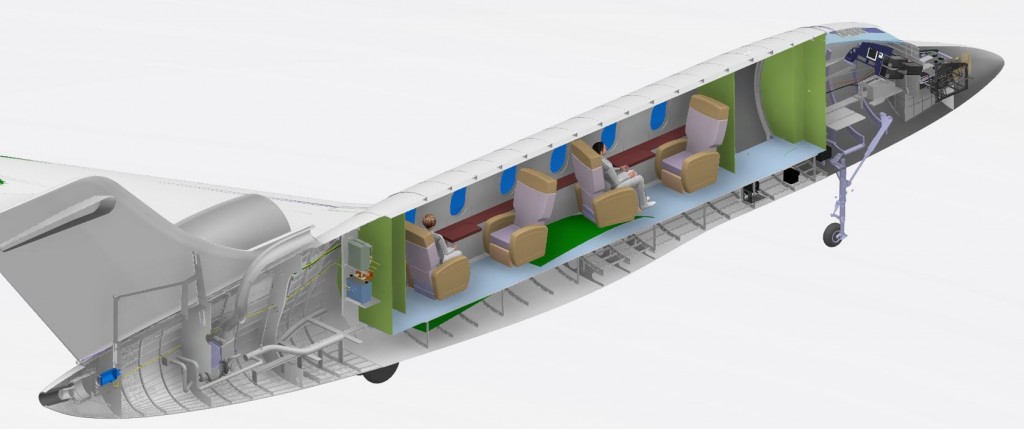

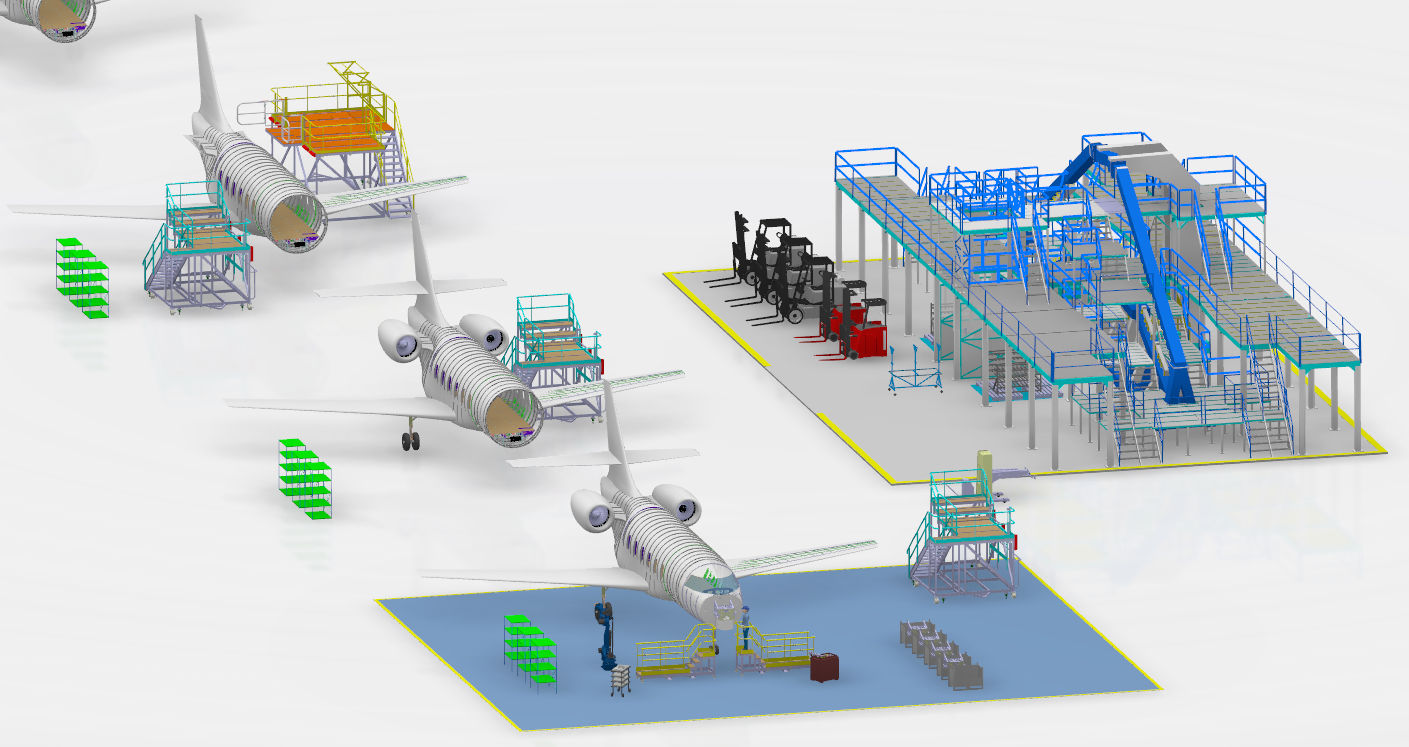

- Industry of future in the aeronautical Field

- Collaborative and international project

- Format successfully proven over four last years

- Unique multidisciplinary engineering project

- Includes weekly online meeting in english

- Innovative project

- Credits : 30ECTS

The industry of the future !

This new edition is about a current topic : The industry of the future ! This topic is present in each country and it is a very interesting point to the students learn and participate to the factory of tomorrow !

This new edition is about a current topic : The industry of the future ! This topic is present in each country and it is a very interesting point to the students learn and participate to the factory of tomorrow !

This new project will follow various orientations like :

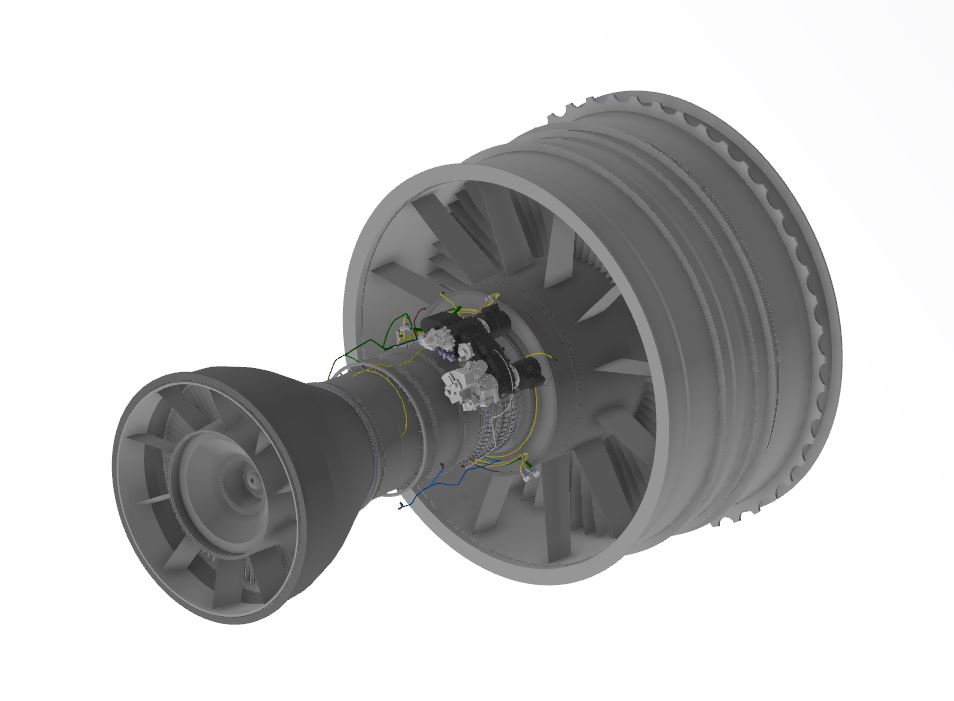

- Mechanical design

- Additive manufacturing using robots

- Cobotics (When people and robots work together)

- Ergonomics and maintenance

- Manufacturing and machining

- Process flow management

- Smart factory design

- Assistance and supervision by drones

See tab « Work packages »