Design an innovative mobile station capable to transport the turbofan between each workstation permitting more flexibility on the production line.

Nowadays in the aeronautical field, factories are using systems to transport the turbofans taking them by the top (see image below), the consequences of these systems are some difficulties when the line production is changing, they must change all the turbofan transport system. This working group will take example from the best new technologies and available equipments (like Kuka robot) to design a system capable to transport parts of the turbofan between each workstation.

Exemple of a turbofan transport

Kuka robot

Activities

- Design a new motorized system, which permits increase the efficiency of the production line and enhance the line flexibility.

- Take into account that the equipment has to be able to manipulate parts of the turbofan (elevate and rotate) and reach a precise positioning in order to place it on each workstation or for example to install it on the plane.

To complete successfully these tasks, we will provide some 3D datas, including among others a Turbofan engine

Turbofan cross-section

Turbofan

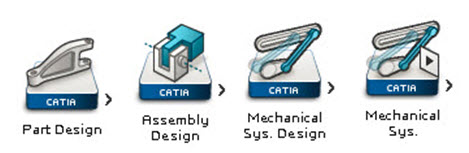

Main 3DEXPERIENCE software applications used