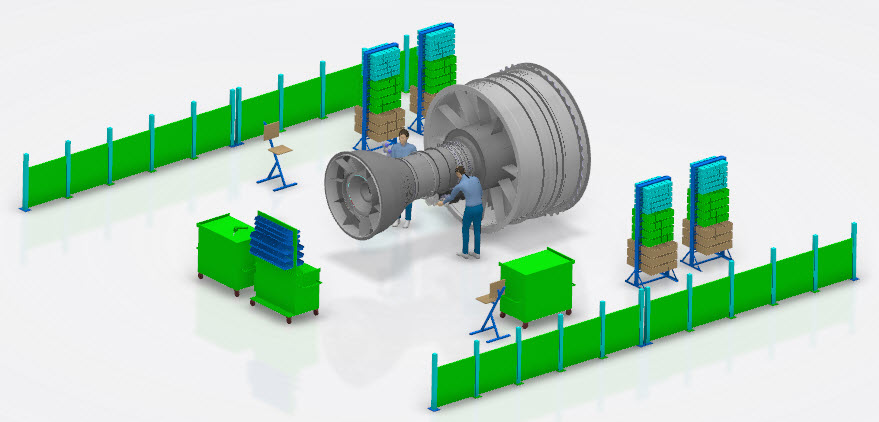

Design and optimize a workstations adapted to our new transport system (see mechanical design tab)

The « collaborative mechanical design » working group will design an innovative system which will transport parts of the turbofan between each workstation. In our innovative Factory, every workstation has to be designed in order to welcome the Turbofan and realize the operations (Manual and automated operations) in the best conditions.

However, we also will work on a plane assembly line.

First group activities

Example of workstation

- Take back the workstation provided and modify it with the objective of enhance the conditions of the workers and the organization with the robots;

- Realize a total ergonomic analysis of the working process (Position, physical efforts…), and make the workstation better (Ergonomic point of view);

- Simulate and record a complete optimized ergonomic operation;

- Document clearly all the processes and results.

Maintenance operation using DELMIA

Ergonomic analysis

Second group activities

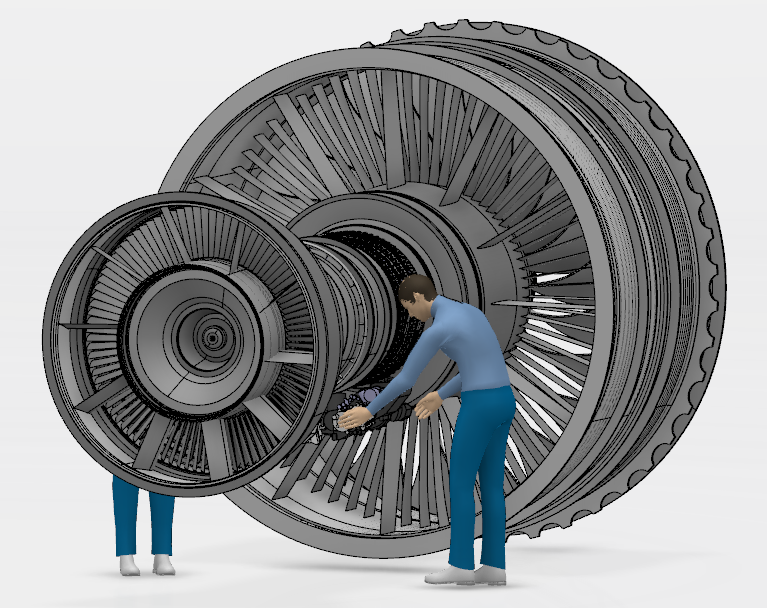

- Simulate maintenance processes on our Turbofan system and plane assembly line;

-

Check accessibility of the workers;

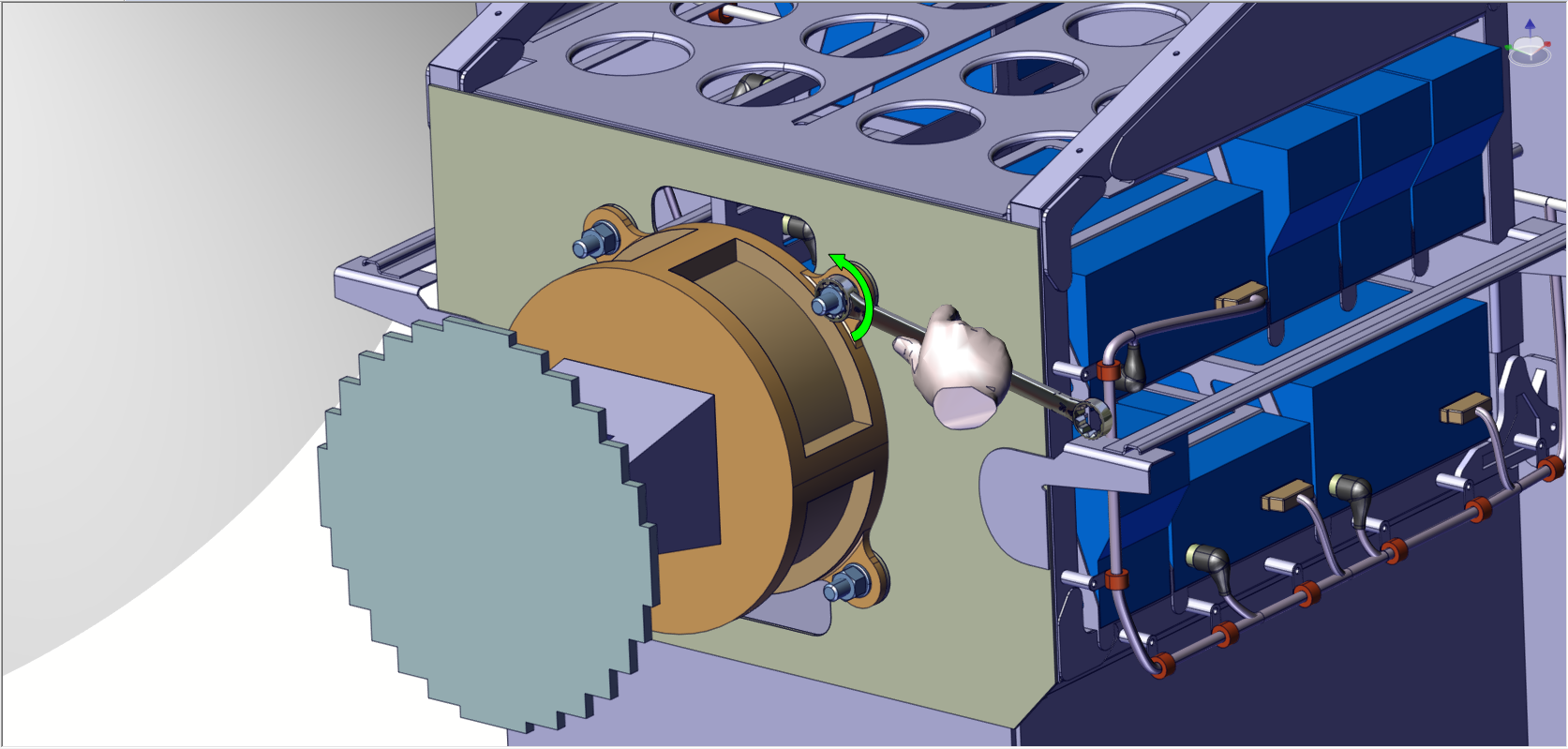

- Document the operation thanks to 3DVia composer;

- Innovate with Oculus vision.

Virtual maintenance operation (Oculus vision)

Maintenance operation using 3DVia Composer

Maintenance operation using 3DVia Composer

3DEXPERIENCE softwares applications used