Proposed by the PLMCC of Hanoi

Collaborative mechanical design

Context: Nowadays in the aeronautical field, step by step the use of composites is more and more significant.

For example, they represent more than 50% of the total material of the Boeing 787 or Airbus A350

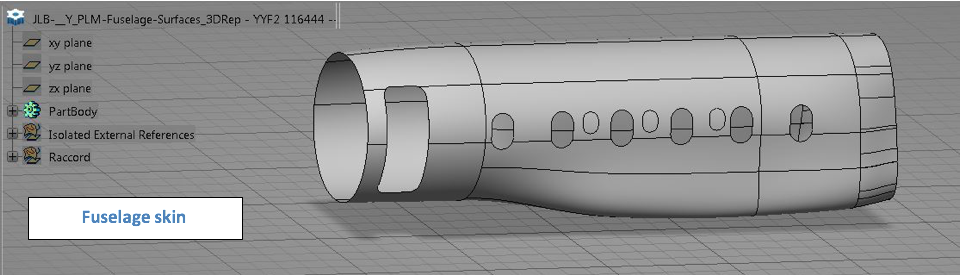

They are massively used for the wings and for structural elements and skin of the fuselage.

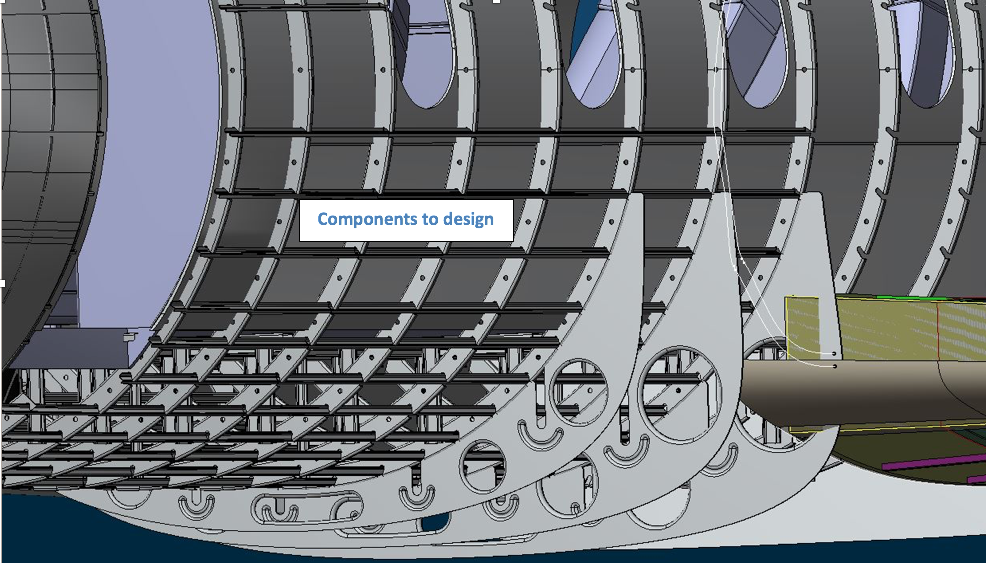

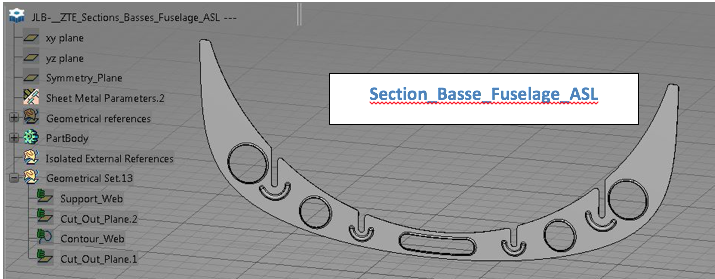

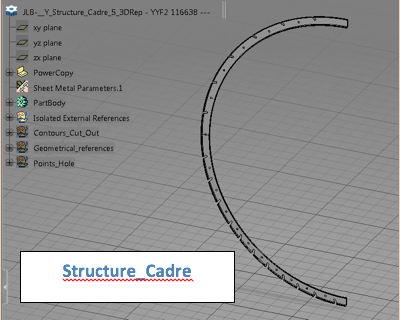

Objective: Design some structural components of the fuselage in composite previously designed in aeronautic sheet metal.

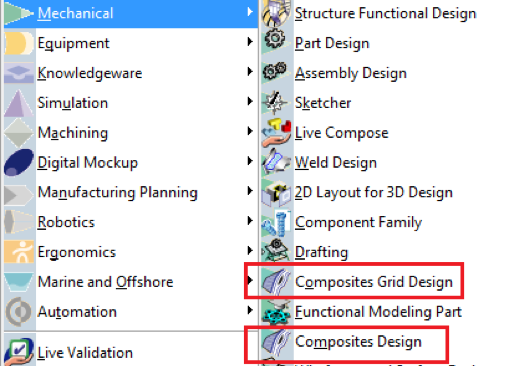

With the Composites Grid Design workshop you will design the new composite components.

With the Composites Design you will verify the manufacturing process

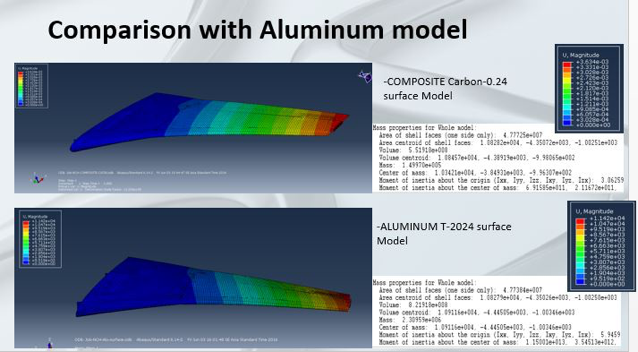

With Abaqus, you will perform a structural Analysis to optimize the design to reinforce the structure and do decrease the weight

3D Data:

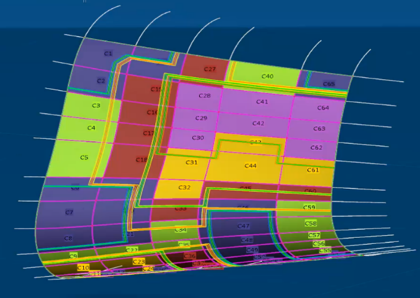

The components to be designed in composites are the following

You will use Catia knowledge to design a set of similar components (Parametric design, Templates, Power copy, optimization)

The system has to be able to reach a precise positioning.

Some Components are still designed in composite.

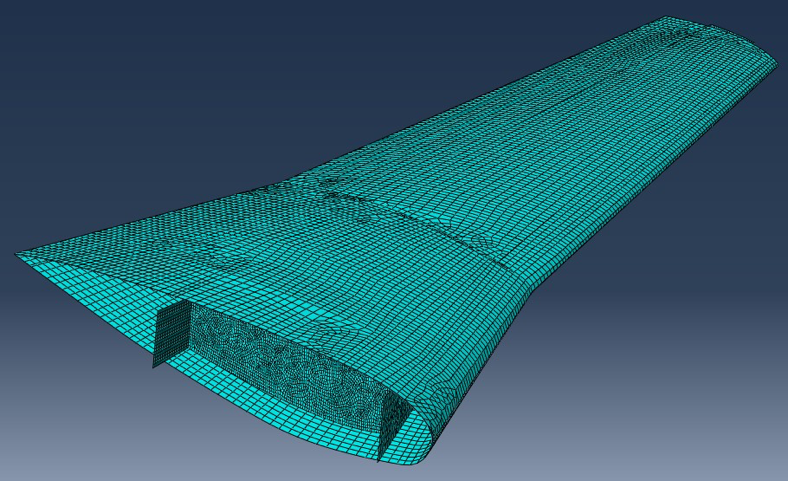

The Wing:

Also simulated I Abaqus for structural analysis and optimization

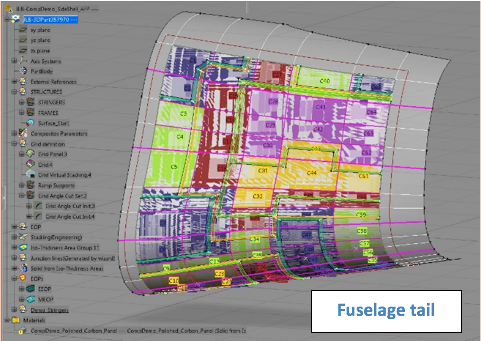

Part of the Tail:

To find your Data search on the 3DEXPERIENCE: MECHANICS_Workstation

| TASKS | DETAILS | SOFTWARE APPLICATIONS | LINKS BETWEEN WORK PACKAGES |

| Analyze the available Composites components:

Wing and Tail

|

Perform a first study of the full Design.

Use the Help of Catia V6. |

CATIA (Composite Design and Composite grid design)

|

-Composite design course ( on 3DS Academy)

-Composite design course (written by PLMCC) -Wing (Catia V6 files) – Tail (Catia V6 files)

|

| Analyze the structure analysis of the wing

|

Analysis done in Abaqus.

Follow the presentation done by You also can follow the embedded course material |

ABAQUS | – Abaqus fundamental course ( on 3DS Academy)

-Abaqus analysis course (written by PLMCC) -Wing (Abaqus 14 files)

|

| Analyze the Composite design method and choose the best method

|

Use and compare the manual approach and grid approach in Catia. Application to the cadre structure and fuselage skin of the B_jet | CATIA (Composite design and Composite grid design) | -Catia V6 files of all B_jet components |

| Optimization of the Composite design

|

After have the 1st version of composite design. The fuselage skin and the cadre structure will be analyzed and optimized in Abaqus.

Using the knowledge to adapt to a set similar components |

CATIA (Composite grid design) and ABAQUS

|

|

| Assembly all the composite components | When the design step and optimized step finished, all the composite components will be assembled | CATIA (Assembly design)

|

-Full B_jet |

| Simulation of the manufacturing process of the composites components

|

choice of a manufacturing process and simulate the manufacturing process of the composites components | CATIA (Composite manufacturing) |

Deliverables (70% percent of the evaluation):

- A first video explaining all the methodology of your work: step by step video detailing the full process. The duration of the video could last until 30 minutes. Voice over in English will be appreciated.

- A second video showing your work: This short video will showcase your work. The duration should last 2 to 5 minutes

- A technical report (Methodology, calculations…)

- The exported dataset with all your work (Export in .3Dxml with authoring)

The others 30% will be focused on:

- Your project’s report (Around 30 pages)

- Your project’s presentation

Your autonomy and participation